Sic Igbt

Energies Free Full Text A New Sic Planar Gate Igbt For Injection Enhancement Effect And Low Oxide Field Html

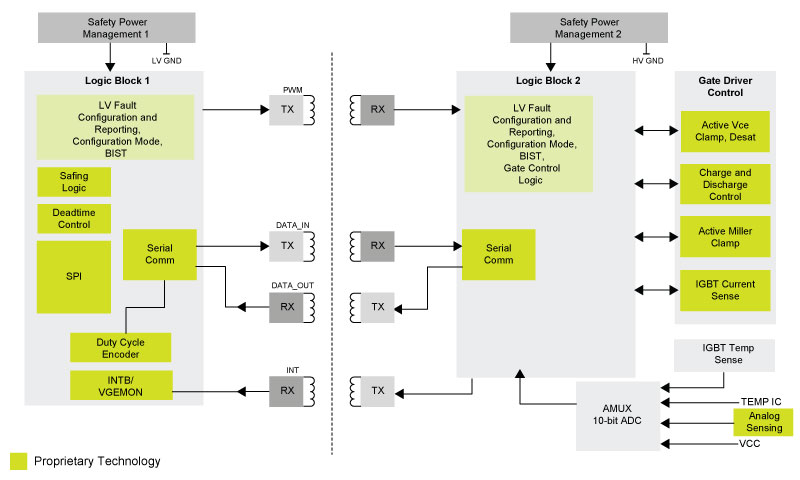

Tida 0030 Sic Igbt Isolated Gate Driver Reference Design With Thermal Diode And Sensing Fet Ti Com

Are You Sic Of Silicon Ev Traction Inverters Using Sic

Using Sic Devices In A Three Phase Motor Drive Application

Www Psma Com Sites Default Files Uploads Tech Forums Semiconductor Presentations Is96 Towards Medium Voltage 33 E2 80 9315kv Sic Devices Pdf

10v Sic Mosfet Vs Silicon Igbt Technology And Cost Comparison Te

Although SiC is a longterm trend, SiC MOSFET is hard to substitute for IGBT in the short run SiC epitaxy production encounters the inconformity of material stress, resulting in epitaxy layer.

Sic igbt. IGBT & SiC Gate Driver Fundamentals Discover solutions to some of the most commonly asked IGBT and SiC gate driver questions While this ebook goes into further detail, you can jump into the most relevant topics for your design at the right. About the comparison of Si insulatedgate bipolar transistor (IGBT) and SiC switching devices—mainly SiC JFETs–have been published Here, usually, the Si devices in matrix converters 2, 3 or standard inverters 4, 5 are replaced by SiC devices, and the change in the system performance is evaluated. The onresistance of conventional silicon power MOSFET structures is too large to serve these applications Consequently, these applications utilize silicon IGBTs today Silicon carbide (SiC) IGBTs offer very promising characteristics for applications that require blocking voltages of above 10–15 kV for use in smart grid applications 3.

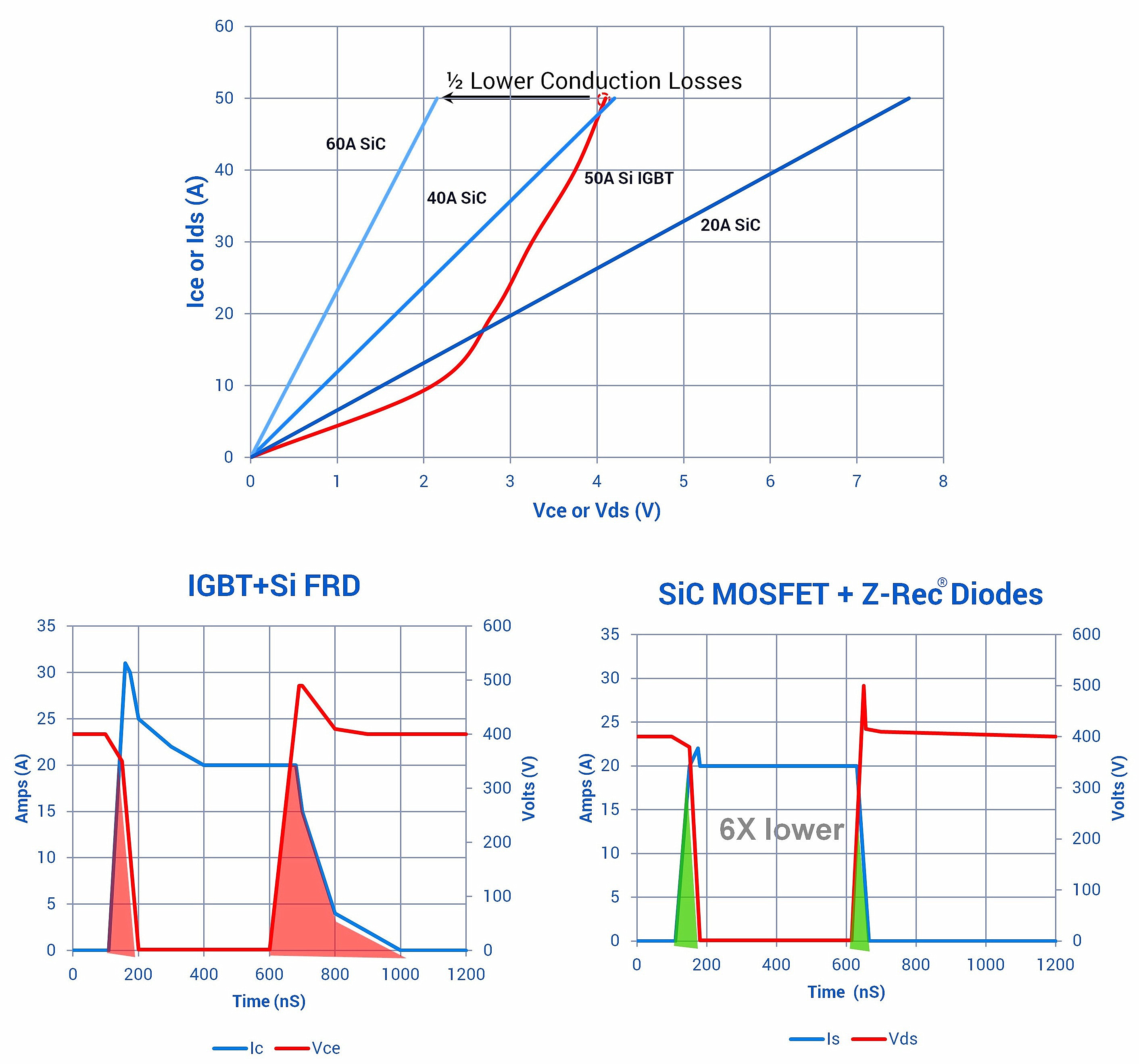

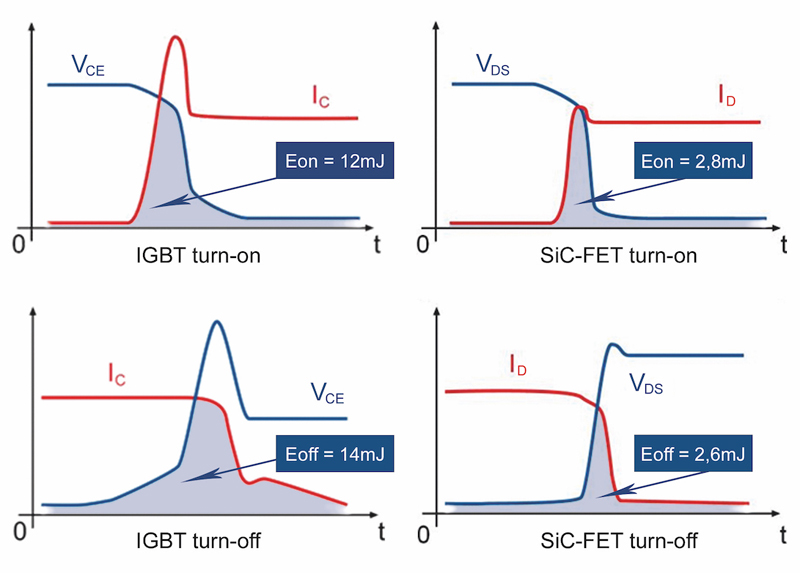

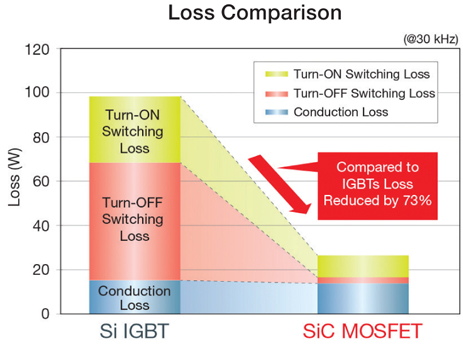

SiC has three times the heat conductivity of silicon, which improves heat dissipation Heat dissipation SiC IPM DIPIPM™ DIPPFC™ SBD MOSFET IGBT Tr FWSW Silicon Carbide Intelligent Power Module DualInLine Package Intelligent Power Module DualInLine Package Power Factor Correction Schottky Barrier Diode Metal Oxide Semiconductor Field. Compared with a 10V Si IGBT (Insulated GateType Bipolar Transistor) Toshiba’s 10V SiC MOSFET offers higher switching speeds, lower ONresistance, about a 77% 1 reduction in turnOFF loss and about 76% 2 reduction in turnON loss, plus lowONvoltage 3 in the draincurrent range below 25A. The Insulated Gate Bipolar Transistor (IGBT) is a minoritycarrier device with high input impedance and large bipolar currentcarrying capability GeneSiC Semiconductor, a pioneer and global supplier of a broad range of Silicon Carbide (SiC) power semiconductors has a healthy offering of IGBTs in its pocket The portfolio of GeneSiC.

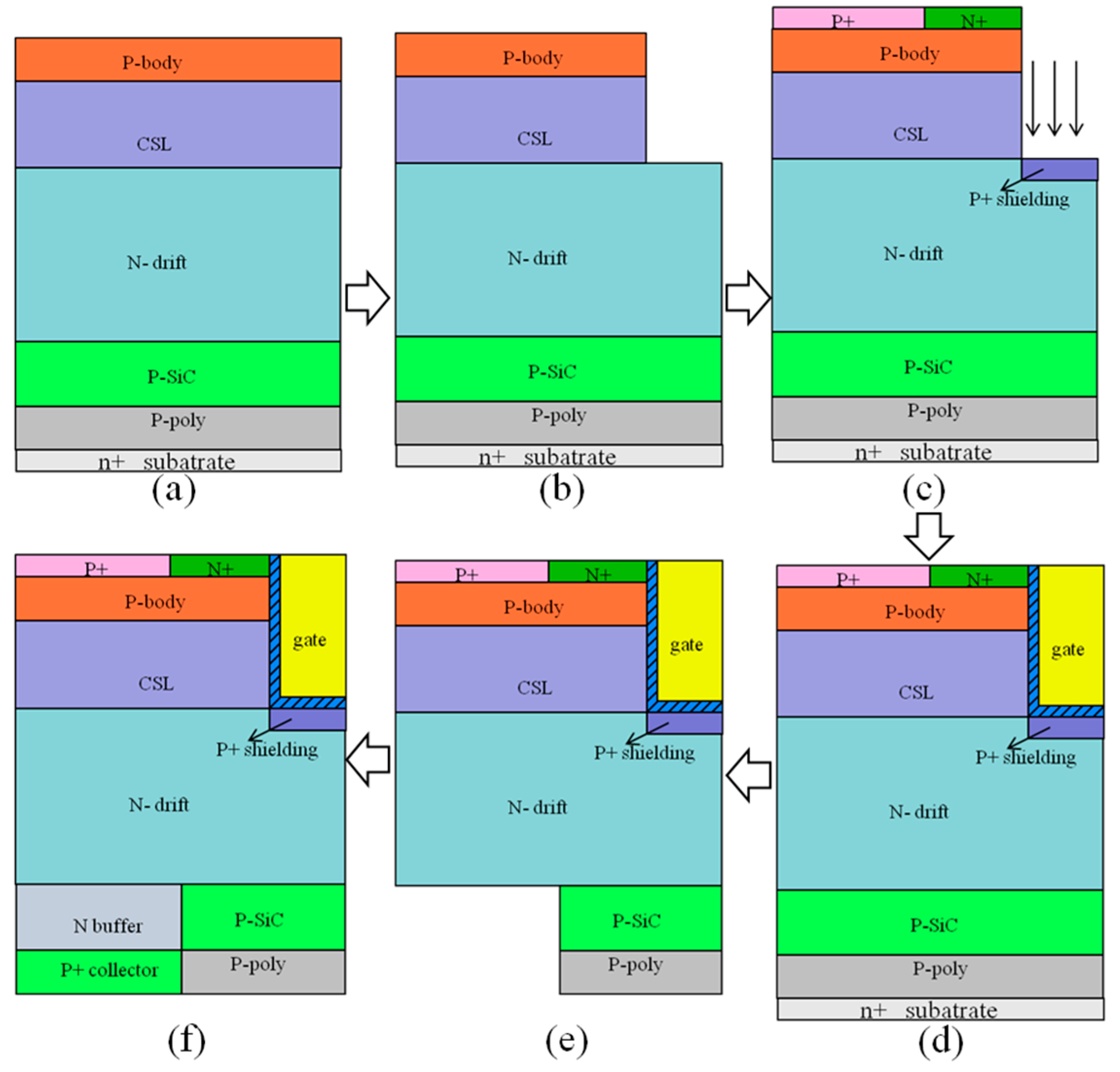

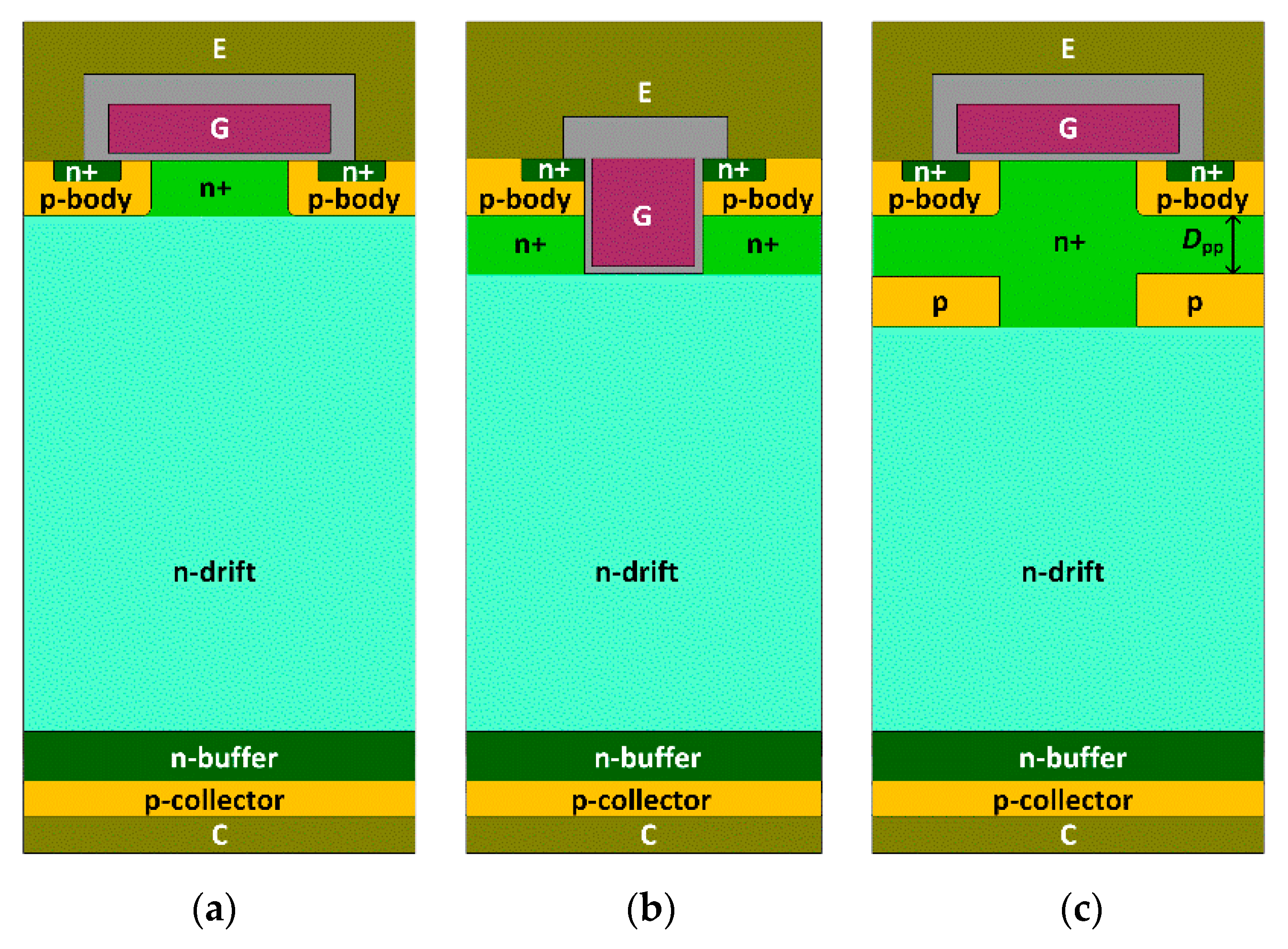

Description This document explains the comparison of Toshiba SiC MOSFET TW070J1B and Si IGBT, by switching loss, conduction loss, diode loss, and total power loss simulation son of SiC MOSFET and Si IGBT. Full SiC power devices, operating at its highest efficiency of 993% and a lower total BOM cost It compares the switching performance, efficiency and thermal performance between this new SiC MOSFET and Si high speed H3 IGBT The experimental results demonstrate that full Cree SiC MOSFETs with SiC schottky diodes allow increased system frequency. Abstract and Figures In this paper, a technology computeraided design (TCAD) model of a silicon carbide (SiC) insulatedgate bipolar transistor (IGBT) has been calibrated against previously.

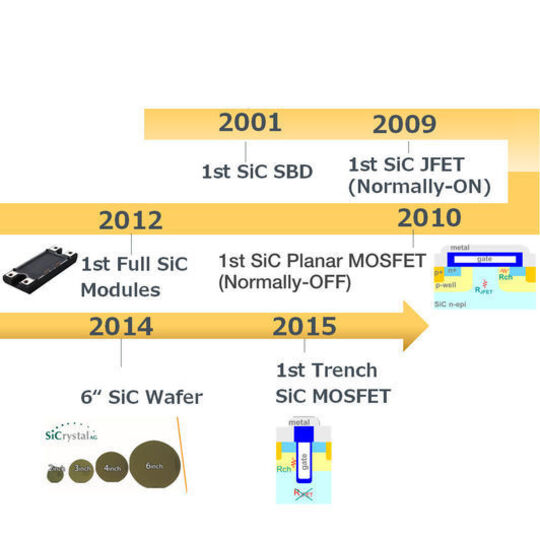

Designs based on insulatedgate bipolar transistor (IGBT) technology One big factor to be overcome is a relatively higher price, which manufacturers are trying to tackle by using larger wafers Another issue concerns instabilities in the threshold voltage level caused by a messy transition region between the pure SiC and. Designs based on insulatedgate bipolar transistor (IGBT) technology One big factor to be overcome is a relatively higher price, which manufacturers are trying to tackle by using larger wafers Another issue concerns instabilities in the threshold voltage level caused by a messy transition region between the pure SiC and. The Next Revolutionary Technology Will Be The SiC MOSFET The silicon IGBT was an enormous positive disruption to the power electronics community in the 1980s, and it has been the workhorse of the industry ever since The next revolutionary technology will be the SiC MOSFET Today’s state of the SiC MOSFET indicates resolution on.

The Next Revolutionary Technology Will Be The SiC MOSFET The silicon IGBT was an enormous positive disruption to the power electronics community in the 1980s, and it has been the workhorse of the industry ever since The next revolutionary technology will be the SiC MOSFET Today’s state of the SiC MOSFET indicates resolution on. SiC (silicon carbide) is a compound semiconductor material composed of silicon (Si) and carbon (C) Table 11 shows the electrical characteristics of each semiconductor material SiC has an excellent dielectric breakdown field intensity (breakdown field) and bandgap (energy gap), which are 10 times and 3 times greater than Si, respectively. Compared to the Si diode with IGBT switch, the SiCdiodewithIGBT combination's switching frequency can be increased from 16 kHz to > 48 kHz with switching losses remaining the same (at input current 5 A) The SiC diode/ SiC MOSFET twosome's switching frequency may even be increased to over 100 kHz.

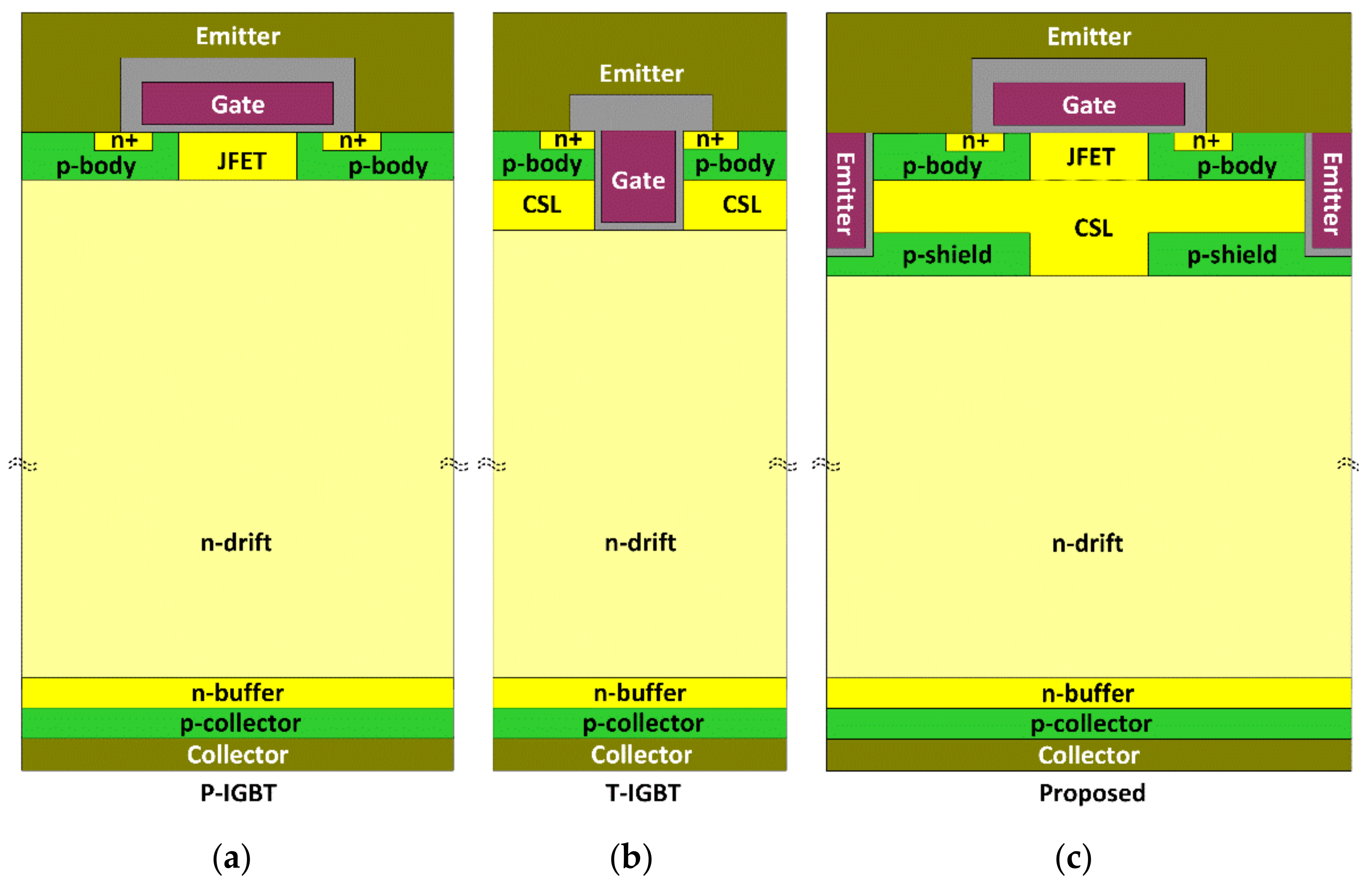

Along with the increasing maturity for the material and process of the wide bandgap semiconductor Silicon Carbide (SiC), the IGBT representing the top level of power devices could be fabricated by. Figure 34 Turnon Switching Loss of SiC MOSFET and Si IGBT From IGBT to SiC MOSFET 33 Turnoff Switching Waveform and Turnoff Switching Loss (Note3) DS S Figure 35 Turnoff Waveform of SiC MOSFE T and Si IGBT Turnon switchingloss E on T a = 25 ºC T a = 150 ºC E on of IGBT (mJ) 25 E on 07of SiC MOSFET (mJ) 06 E on reduction r ate. The Insulated Gate Bipolar Transistor (IGBT) is a minoritycarrier device with high input impedance and large bipolar currentcarrying capability GeneSiC Semiconductor, a pioneer and global supplier of a broad range of Silicon Carbide (SiC) power semiconductors has a healthy offering of IGBTs in its pocket The portfolio of GeneSiC.

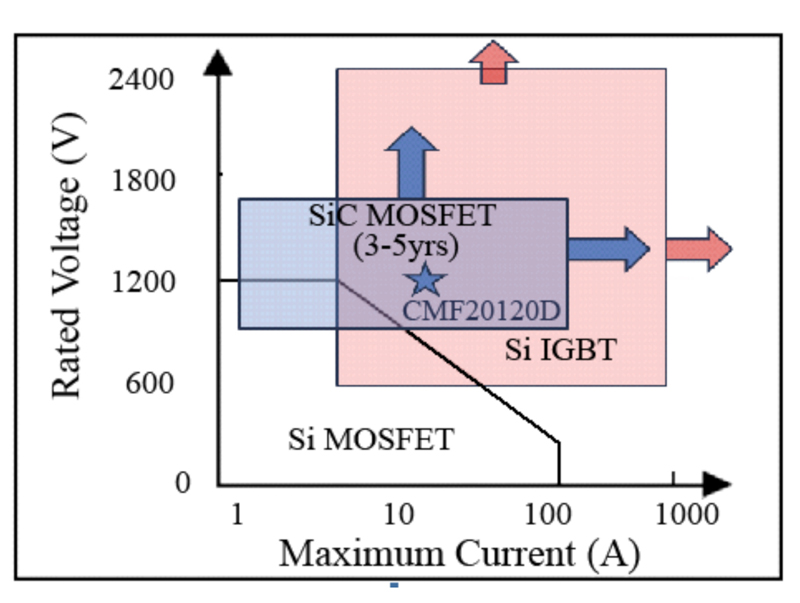

IGBTs, SiC and other technologies are geared for the nicheoriented markets at 1,700 volts and. Figure 17 65 kV FullSiC power module in HV100 package with 102 kV insulation voltage Figure 18 Comparison of switching loss between SiIGBT at 150°C, SiCMOSFET and SBDembedded SiCMOSFET at 175°C 13 Conclusion. The SiC web forum provides you with a platform for exchanging ideas with the community, asking our Silicon Carbide experts for advice and for sharing your experience with CoolSiC™ MOSFET modules and discretes Register today and join the conversation!.

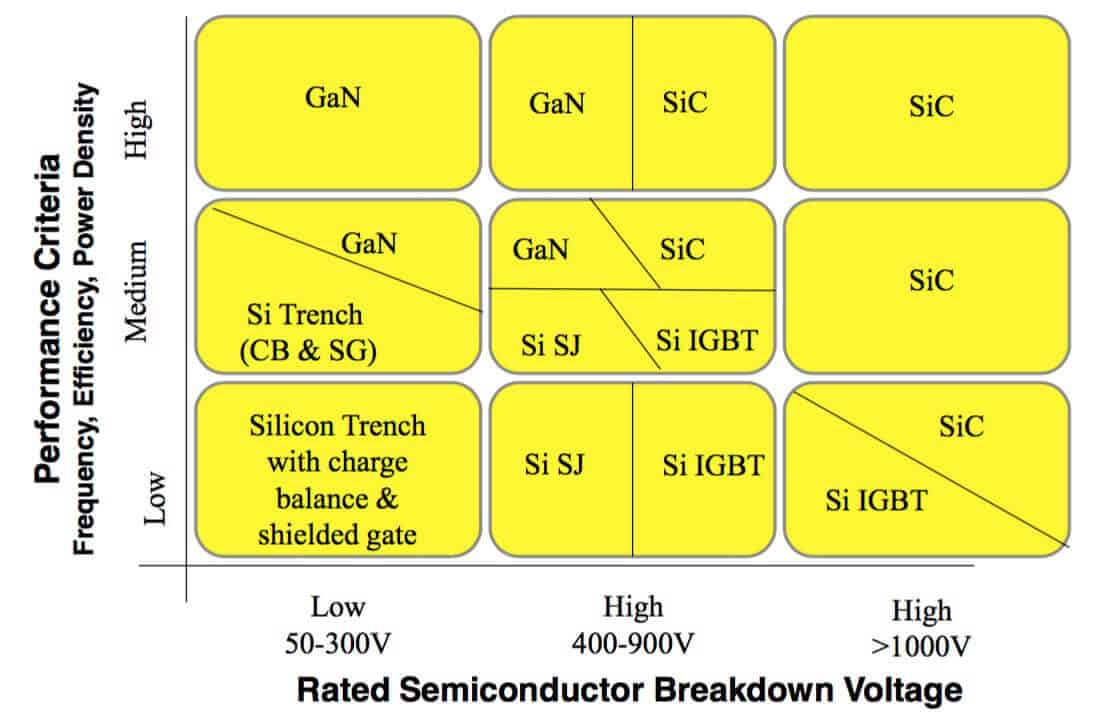

In comparison to traditional Silicon based switches like IGBTs and MOSFETs, the Silicon Carbide (SiC) MOSFET offers a series of advantages CoolSiC™ MOSFET products in 1700 V, 10 V and 650 V target photovoltaic inverters, battery charging energy storage, motor drives, UPS, auxiliary power supplies and SMPS. Designs based on insulatedgate bipolar transistor (IGBT) technology One big factor to be overcome is a relatively higher price, which manufacturers are trying to tackle by using larger wafers Another issue concerns instabilities in the threshold voltage level caused by a messy transition region between the pure SiC and. About the comparison of Si insulatedgate bipolar transistor (IGBT) and SiC switching devices—mainly SiC JFETs–have been published Here, usually, the Si devices in matrix converters 2, 3 or standard inverters 4, 5 are replaced by SiC devices, and the change in the system performance is evaluated.

SiC FETs are targeted for 600volt to 10kilovolt applications Another technology, GaN, is a binary IIIV material In the power arena, GaNonsilicon chips are used in 30 to 600volt applications GaN has a bandgap of 34 eV The best technology?. Wolfspeed is the premier provider of the most fieldtested SiC, GaN Power, and RF solutions in the world We are the world leader in silicon carbide and our fieldtested RF components dominate the field Powering more Consuming less Wolfspeed, A Cree Company. • Si IGBT device 25A(@100°C) 10V ST trench gate fieldstop IGBT (T jmax =175°C) • SiC switching power losses are considerably lower than the IGBT ones • At high temperature, the gap between SiC and IGBT is insurmountable SiC MOSFET is the optimal fit for High Power, High Frequency and High Temperature applications SiC MOSFET.

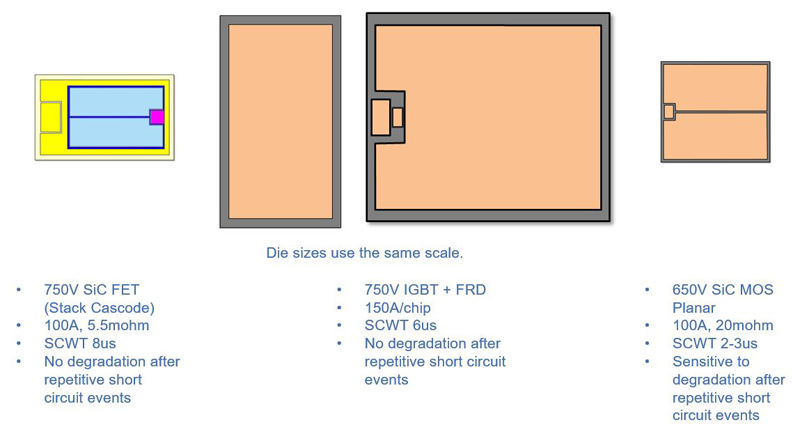

V IGBT modules using two 1cm x 1cm IGBT die vs a 0 A, 10 V SiC FET module with two 06 x 06 cm SiC stack cascode die Figure 4 Conduction loss for 10 V SiC FETs with 36% of the comparison IGBT chip area In this 0 A, 10 V module, ONstate voltage drop with SiC FETs is much lower than the IGBT drop for all currents below 0 A, both. 1700V FullSiC modules to replace IGBTs StarPower offers a range of FullSiC half bridge modules in an industry standard 62mm package Detail New series of 1700V IGBT modules Cadenazzo, Switzerland, 0705 – StarPower pleased to announce the launch of its new power modules for multiple applications. From Si IGBT in TO247 to SiC MOSFETs in molded package PntPower missed an analyst publication from August 17 stating that ST Microelectronics was selected as a main supplier for Tesla Model 3 thanks to its SiC MOSFET at 650V ST Microelectronics, at the time, was among the most advanced companies in SiC MOSFETs with a 10V device already.

SiC (silicon carbide) is a compound semiconductor material composed of silicon (Si) and carbon (C) Table 11 shows the electrical characteristics of each semiconductor material SiC has an excellent dielectric breakdown field intensity (breakdown field) and bandgap (energy gap), which are 10 times and 3 times greater than Si, respectively. Virtually no diode switching losses and significantly reduced IGBT turnon losses;. SiC has approximately 10 times the critical breakdown strength of silicon Furthermore, the drift layer that is a main cause of electrical resistance is onetenth of the thickness This allows a large reduction in electrical resistance and, in turn, reduces power loss.

Silicon carbide (SiC), also known as carborundum / k ɑːr b ə ˈ r ʌ n d əm /, is a semiconductor containing silicon and carbonIt occurs in nature as the extremely rare mineral moissaniteSynthetic SiC powder has been massproduced since 13 for use as an abrasiveGrains of silicon carbide can be bonded together by sintering to form very hard ceramics that are widely used in applications. • Only four 15 kV SiC IGBTs are sufficient for 72kV AC singlephase (72kV is singlephase of 3phase 1247kV) grid integration, whereas, at least twelve 65 kV Si IGBTs are needed for the same voltage • This HBridge test showcases the MV power conversion possibilities of the Cree developed 15kV SiC IGBT device funded byARPAE/DOE. SiC devices have excellent characteristics that realize high blocking voltage, low power dissipation, highfrequency operation and hightemperature operation Power semiconductors that make use of SiC achieve significant reduction in energy consumption, and can be used to develop smaller and lighter products.

SiC devices have excellent characteristics that realize high blocking voltage, low power dissipation, highfrequency operation and hightemperature operation Power semiconductors that make use of SiC achieve significant reduction in energy consumption, and can be used to develop smaller and lighter products. SiC (silicon carbide) is a compound semiconductor material composed of silicon (Si) and carbon (C) Table 11 shows the electrical characteristics of each semiconductor material SiC has an excellent dielectric breakdown field intensity (breakdown field) and bandgap (energy gap), which are 10 times and 3 times greater than Si, respectively. *1 MMass production, WWorking sample, UUnder development, DDiscontinued *2 The first publication of the papers was at PCIM Europe Conference 18.

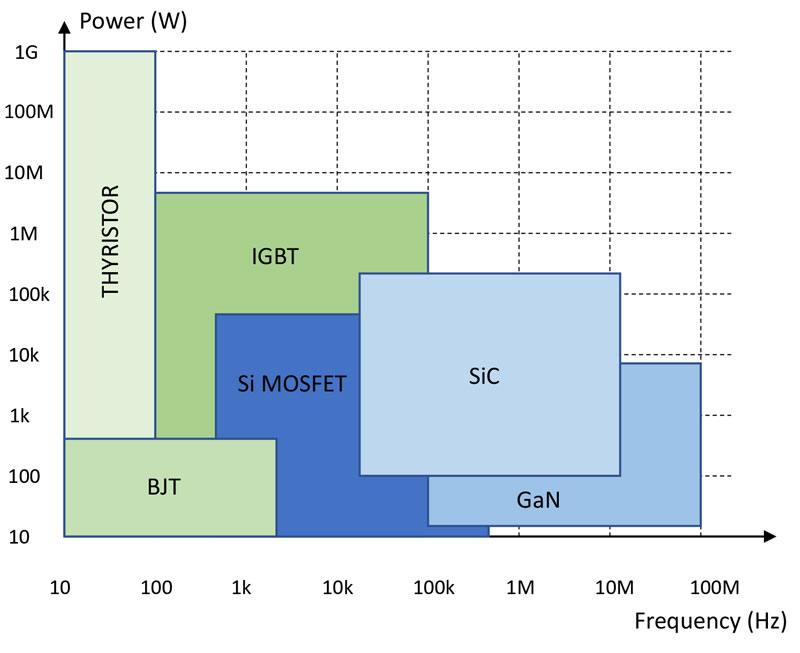

IGBTmodulebased power assemblies with SiC modules In recent years, 12kV and 17kV silicon carbide (SiC) MOSFETs have become a real alternative for power converter designers who currently use IGBTs To date, the majority of the SiC MOSFET design wins have occurred in power converters. IGBT Very high power, high voltage, medium frequency up to 50 kHz HV motor control, HA, UPS, welding, induction heating, main traction, SiC MOSFET Very high power, high voltage, high frequency, high temperature. SiC power devices are showing developers advantages like less loss, smaller size, and improved efficiency Innovations like this will continue to push the limits of MOSFETs and IGBTs into highervoltage and higherpower applications.

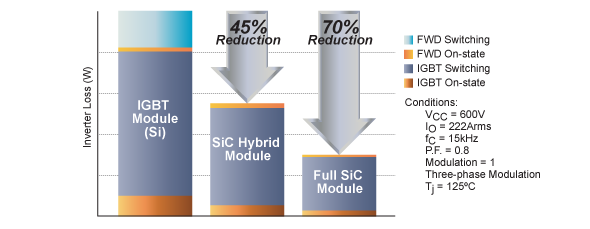

Hybrid SiC modules 50% lower power losses and easy implementation Combination of IGBT switches with silicon carbide Schottky freewheeling diodes;. 1700V FullSiC modules to replace IGBTs StarPower offers a range of FullSiC half bridge modules in an industry standard 62mm package Detail New series of 1700V IGBT modules Cadenazzo, Switzerland, 0705 – StarPower pleased to announce the launch of its new power modules for multiple applications. IGBT Very high power, high voltage, medium frequency up to 50 kHz HV motor control, HA, UPS, welding, induction heating, main traction, SiC MOSFET Very high power, high voltage, high frequency, high temperature.

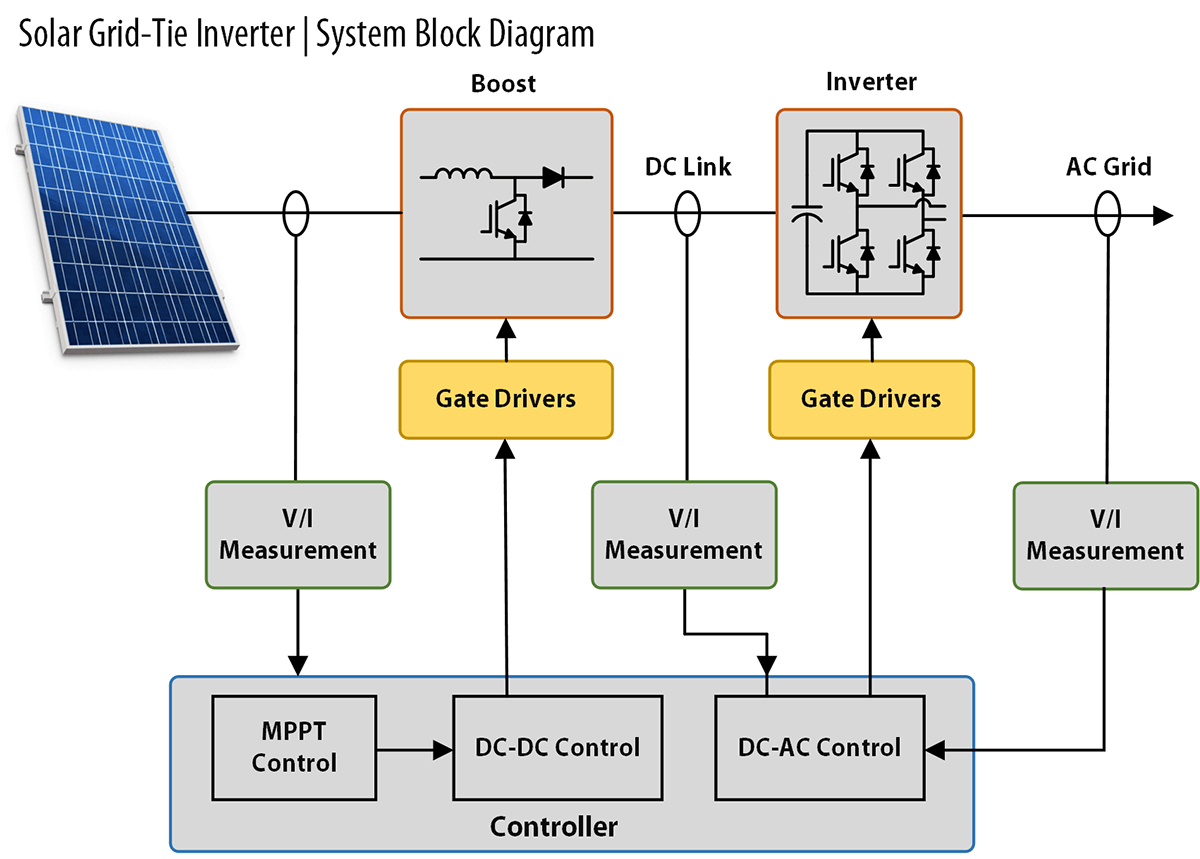

Using the novel field stop 4th generation IGBT technology and the 15th generation SiC Schottky Diode technology, AFGHL75T65SQDC offers the optimum performance with both low conduction and switching losses for high efficiency operations in various applications, especially totem pole bridgeless PFC and Inverter. Along with the increasing maturity for the material and process of the wide bandgap semiconductor Silicon Carbide (SiC), the IGBT representing the top level of power devices could be fabricated by. Optional SiC/IGBT Switches The inverter can be factory configured with either SiC or IGBT switches High frequency applications, such as, solar PV inverters and active rectifiers are more likely to use SiC switches Whereas, motor drive applications can suffice with low switching frequency IGBT switches.

Silicon Carbide (SiC) is an innovative technology that will replace silicon in many applications The idea of using SiC for electric vehicles (EVs) was born when efforts were made to increase the efficiency and range of such vehicles, while reducing the weight and cost of the entire vehicle and thus increasing the power density of control electronics. IGBT and SiCMOSFET technologies are using different ±output voltages so we have developed two models supporting each technology As our DC/DC converter has an output stabilizing function, it can support a widerange input voltage (DC13 to 28V), instead of the usual restrictive DC15V. V IGBT modules using two 1cm x 1cm IGBT die vs a 0 A, 10 V SiC FET module with two 06 x 06 cm SiC stack cascode die Figure 4 Conduction loss for 10 V SiC FETs with 36% of the comparison IGBT chip area In this 0 A, 10 V module, ONstate voltage drop with SiC FETs is much lower than the IGBT drop for all currents below 0 A, both.

Although SiC is a longterm trend, SiC MOSFET is hard to substitute for IGBT in the short run SiC epitaxy production encounters the inconformity of material stress, resulting in epitaxy layer. About the comparison of Si insulatedgate bipolar transistor (IGBT) and SiC switching devices—mainly SiC JFETs–have been published Here, usually, the Si devices in matrix converters 2, 3 or standard inverters 4, 5 are replaced by SiC devices, and the change in the system performance is evaluated. =175°C) • SiC switching power losses are considerably lower than the IGBT ones • At high temperature, the gap between SiC and IGBT is insurmountable SiC MOSFET is the optimal fit for High Power, High Frequency and High Temperature applications SiC MOSFET SiC MOSFET Driving Requirements 14.

Limits arising from a minority carrier dynamics which is known from an IGBT, eg a limited current handling capability at turnoff and high VDS, does not apply Latchup effects, turnon of a bipolar pnp transistor, are suppressed by the high VBE (due to Vbi of SiC pn junctions) required to activate a parasitic bipolar transistor and by the. However, SiC based IGBT and thyristors are currently under development 5 27 15 Currently, the only available IGBTbased SiCdevices are socalled hybrid devices with traditional Si transistor and SiC Schottky Barrier Diode (SBD) SiC benefits. SiC has approximately 10 times the critical breakdown strength of silicon Furthermore, the drift layer that is a main cause of electrical resistance is onetenth of the thickness This allows a large reduction in electrical resistance and, in turn, reduces power loss.

Hitachi Power Semiconductor Device Hitachi High Voltage IGBTs have been corresponding to a wide range of applications such as railway applications and various power conveters, leading companies for domestic and overseas adopt them, since they were adopted as a railway application in 1992. SiC has approximately 10 times the critical breakdown strength of silicon Furthermore, the drift layer that is a main cause of electrical resistance is onetenth of the thickness This allows a large reduction in electrical resistance and, in turn, reduces power loss. • Si IGBT device 25A(@100°C) 10V ST trench gate fieldstop IGBT (T jmax =175°C) • SiC switching power losses are considerably lower than the IGBT ones • At high temperature, the gap between SiC and IGBT is insurmountable SiC MOSFET is the optimal fit for High Power, High Frequency and High Temperature applications SiC MOSFET.

In comparison to traditional Silicon based switches like IGBTs and MOSFETs, the Silicon Carbide (SiC) MOSFET offers a series of advantages CoolSiC™ MOSFET products in 1700 V, 10 V and 650 V target photovoltaic inverters, battery charging energy storage, motor drives, UPS, auxiliary power supplies and SMPS. IGBT & SiC Gate Driver Fundamentals Discover solutions to some of the most commonly asked IGBT and SiC gate driver questions While this ebook goes into further detail, you can jump into the most relevant topics for your design at the right. 1700V FullSiC modules to replace IGBTs StarPower offers a range of FullSiC half bridge modules in an industry standard 62mm package Detail New series of 1700V IGBT modules Cadenazzo, Switzerland, 0705 – StarPower pleased to announce the launch of its new power modules for multiple applications.

Compared to the Si diode with IGBT switch, the SiCdiodewithIGBT combination's switching frequency can be increased from 16 kHz to > 48 kHz with switching losses remaining the same (at input current 5 A) The SiC diode/ SiC MOSFET twosome's switching frequency may even be increased to over 100 kHz.

Xm3 Silicon Carbide Power Modules Wolfspeed

Comparison Between Si Igbt And Sic Mosfet Modules A Cross Section Of Download Scientific Diagram

Sic Gan Technologies Upset The Traditional Benchmarks Of The Igbt Industry I Micronews

Micromachines Free Full Text Simulation Study Of 4h Sic Trench Insulated Gate Bipolar Transistor With Low Turn Off Loss Html

Wechselrichter Leistungsvergleich Von Si Igbt Und Sic Mosfet All Electronics

Switching Losses Of Si Igbt And Sic Mosfet Under Inductive Load Test Download Scientific Diagram

Gd3100 Single Channel Gate Driver For Igbts Sic Nxp

Output Characteristics I C I D Versus V Ce V Ds Of Si Igbt Download Scientific Diagram

Sic Mosfets The Perfect Fit For Modern Electrical Vehicles

Driving Sic Fets And Igbts

10v Sic Mosfet Vs Silicon Igbt Technology And Cost Comparison Te

Rohm Now Offering Sic Igbts And Gate Drivers In India News

Sic Based Mosfets Offer Dramatic Benefits In Automotive Power Applications Edn

Cost Competitive Sic

Crystals Free Full Text Exploring Sic Planar Igbts Towards Enhanced Conductivity Modulation Comparable To Sic Trench Igbts Html

Differences With Igbts Basic Knowledge Rohm Tech Web Technical Information Site Of Power Supply Design

Switching Pattern For The Sic Mosfet Si Igbts Hybrid Device Download Scientific Diagram

A 13 Kv 4h Sic N Channel Igbt With Low Rdiff On And Fast Switching Scientific Net

Investigations Of P Shielded Sic Trench Igbt With Considerations On Ie Effect Oxide Protection And Dynamic Degradation Semantic Scholar

Sic Igbts Power Microelectronics Device And Process Technologies

Mitsubishi Electric Semiconductors Devices Product Information Power Modules Sic Power Modules

Analysis And Compact Modeling Of Temperature Dependent Switching In Sic Igbt Circuits Sciencedirect

Analysis And Compact Modeling Of Temperature Dependent Switching In Sic Igbt Circuits Sciencedirect

4 Leg Sic Igbt Inverter Module Introduction Part 1 Youtube

Comparison Study Of 12kv N Type Sic Igbt With 10kv Sic Mosfet And 6 5kv Si Igbt Based On 3l Npc Vsc Applications Semantic Scholar

The Challenges For Sic Power Devices Ee Times Europe

10v Silicon Igbt Vs Sic Mosfet Comparison 18 System Plus Consulting

Silicon Carbide A Love Hate Relationship Ee Times

Sic And Gan Vs Igbts The Imminent Tug Of War For Supremacy Power Electronics

Lateral Gan Transistors A Replacement For Igbt Devices In Automotive Applications

Sic Gan Technologies Upset The Benchmarks Of The Igbt Industry Industry News Hinton Information Services

Demystifying Sic Mosfets Challenges Power Electronics News

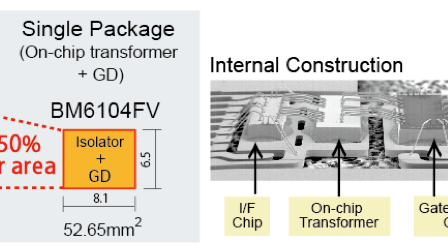

Rohm S Gate Driver Ic With Built In Isolator Optimal For Sic Mosfet Igbt And Power Mosfet Rohm Co Ltd

Igbt Sic Feature Hitachi Power Semiconductor Device Ltd

Ieeexplore Ieee Org Iel7 Pdf

Q Tbn And9gcregu5uhinz 17kasw7st1xd12qcniy E1nthkhcvjn71ga5cig Usqp Cau

10v Silicon Igbt Vs Sic Mosfet Comparison 18 System Plus Consulting

10v Igbt Tandem Power Module Takes On Sic

Silicon Carbide S Superpowers

Sic Power Modules Rohm Mouser

The Industry S First Mass Produced Sic Mos Module Without A Schottky Diode Rohm Semiconductor Rohm Co Ltd

Xm3 Silicon Carbide Power Modules Wolfspeed

Sic General Information Silicon Carbide Littelfuse

Sic And Gan Vs Igbts The Imminent Tug Of War For Supremacy Power Electronics

Silicon Carbide Sic Mosfet Relays For High Power Apps Refurvo Llc

Loss Comparison Between Sic Mosfet And Si Igbt Toshiba Electronic Devices Storage Corporation Europe Emea

Fabrication Of 4h Sic N Channel Igbts With Ultra High Blocking Voltage

Silicon Carbide Sic Power Modules Semikron

What Are Mosfets Super Junction Mosfet Basic Knowledge Rohm Tech Web Technical Information Site Of Power Supply Design

Loss Comparison Between Sic Mosfet And Si Igbt Toshiba Electronic Devices Storage Corporation Europe Emea

Powerex Full Sic Hybrid Sic Igbts Darrah Electric Blog

Comparison Of 6 5 Kv 25 A Igbt And 10 Kv Sic Mosfet In Solid State Transformer Application

Rohm S Gate Driver Ic With Built In Isolator Optimal For Sic Mosfet Igbt And Power Mosfet Rohm Co Ltd

Www Infineon Com Dgdl Infineon The Future Of Power Semiconductors Bodos Power Article V01 00 En Pdf Fileid 5546dbd0cf3081bda

Loss Comparison Between Silicon Igbt And Sic Mosfets Electronics Lab Com

Q Tbn And9gcty7syp5wkorwqiinhmrkqlhsml7qb3gikg Cxccov Zulyveis Usqp Cau

Differences With Igbts Basic Knowledge Rohm Tech Web Technical Information Site Of Power Supply Design

Differences With Igbts Basic Knowledge Rohm Tech Web Technical Information Site Of Power Supply Design

Ai Powered Architecture Unleashes Future Silicon Igbt And Sic Improvements Technical Articles

Www Mouser Com Pdfdocs Are You Sic Of Silicon Part 1 Pdf

Gate Driver Circuit Optimization For Sic Power Devices Power Electronics News

Mitsubishi Electric Semiconductors Devices Product Information Power Modules Sic Power Modules

10v Sic Mosfet Vs Silicon Igbt Technology And Cost Comparison Te

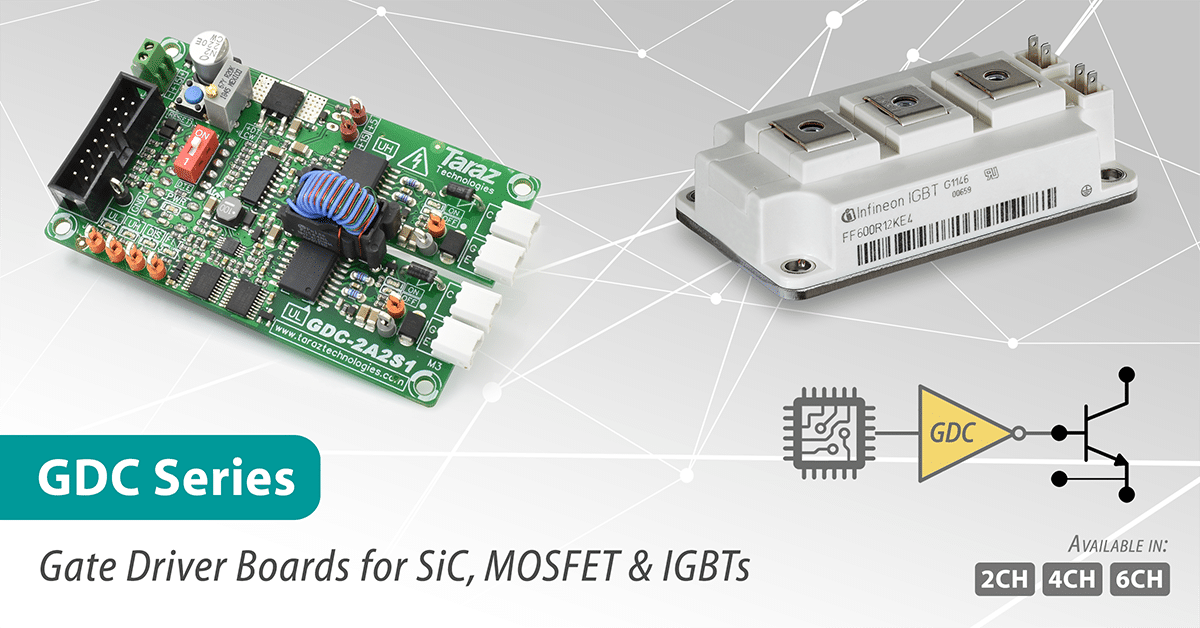

Gate Driver Boards For Sic Mosfet And Igbts Taraz Technologies

Analog Circuits High Voltage Mosfets Scr Igbt Sic Diodes

Typical Output Characteristics Of Si Igbt Si Mosfet And Sic Mosfet Download Scientific Diagram

Isolated Gate Drivers With Integrated Sensing And Improved Advanced Monitoring For Igbts And Sic Mosfets

Q Tbn And9gcruvkcvbhctp3hej5teajzuxjfqshlo2x4ysiqzal4q4zzir4by Usqp Cau

Sic Power Device Team

Performance Improvement Of Gt 10kv Sic Igbts With Retrograde P Well Scientific Net

Search Abb Com Library Download Aspx Documentid Si Carbide concept Pcim 15 Languagecode En Documentpartid Action Launch

Sic Mosfet Datasheet And Comparison To Igbt Youtube

Gate Driver Boards For Sic Mosfet And Igbts Taraz Technologies

Www Nist Gov Document Nistmwdrivesworkshopsbver9pdf

Tipps Fur Den Umstieg Vom Igbt Zum Sic Mosfet

10v Sic Mosfet Vs Silicon Igbt Technology And Cost Comparison System Plus Consulting

Figure 1 From Sic Trench Igbt With Diode Clamped P Shield For Oxide Protection And Enhanced Conductivity Modulation Semantic Scholar

From Igbt To Sic Mosfet A Stone Step For Smooth Replacement In Industrial Applications Technical Articles

Littelfuse Ix4351ne Sic Mosfet Igbt Driver Wins Annual Power Product Award Electronics Lab Com

Mosfet Or Igbt Igbt Vs Mosfet Explanations

Cross Section Of 4h Sic N Igbt Reproduced With Permission From E V Download Scientific Diagram

Inverter Design Optimized Using All Sic Power Devices Electronic Products

4h Sic Trench Igbt With Lower On State Voltage Drop Sciencedirect

Www Nist Gov Document Bhattacharyanist Doe Mv Grid Presentation April1516sbver5pdf

Planet Analog Sic Switches In Electric Vehicles Will They Dominate The Drivetrain

Http Onlinelibrary Wiley Com Doi 10 1002 Eej Pdf

Littelfuse Ix4351ne Sic Mosfet Igbt Driver 翹慧事業股份有限公司

Ieeexplore Ieee Org Iel7 Pdf

Power Converter Reduce Cost And Reach The Market Powerforge

Www Richardsonrfpd Com Docs Rfpd Powerex Sic Pdf

Sic Demand Growing Faster Than Supply

Considerations When Comparing Sic And Gan In Power Applications

High Performance Complements High Reliability Ee Publishers

App Note Comparison Of Sic Mosfet And Si Igbt Dangerous Prototypes

Www s Conferences Org Articles sconf Pdf 19 13 sconf Sefet19 Pdf

Mitsubishi Electric Semiconductors Devices Product Information Power Modules Sic Power Modules

Market Analysis Who Really Requires Gan Sic Power Devices